Ever-Cushion™ Foam Fenders

Ever-CushionTM Netted Foam Filled Marine Fenders

visit www.evergreen-maritime.com to get more information.

Evergreen manufactures the Ever-Cushion netted style foam filled marine fenders as the domestic standard in the industry and meets the most stringent quality and performance demands providing tough heavy-duty fendering systems for harbor, offshore and ship-to-ship applications. The widely used projects proven our Ever-Cushion foam fender is your best guarantee.

Construction Features:

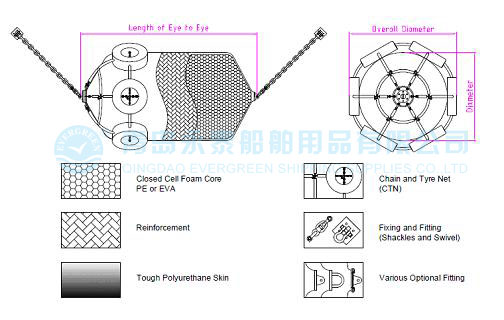

The Ever-CushionTM netless foam marine fenders construction consists of:

A. A superior external chain and tire net, heavy-duty rubber tubing and chains that are connected at every intersection with a shackle. This is the key element in the Ever-Cushion marine fenders un-surpassed strength and resilience.

B. The Ever Cushion™ has a heat laminated 100% closed cell and resilient foam core that is energy absorbing and cannot be ruptured. This fabrication process uses no adhesives, which decomposes after time therefore making the Ever-Cushion™ superior in quality, durability and function. This resilient foam-filled construction provides an unsinkable fender body that permits high energy absorption with a relatively low reaction force compared to most other fendering systems.

C. In order enhance the performance of foam fenders, the Ever-Cushion™ foam fenders skin is constructed of tough and thick nylon filament reinforced polyurethane skin. The skin also has a nylon tire cord applied in a helix pattern during the coating that embeds the filament into the skin. Special layers are applied to both ends where stresses are highest. This advanced process makes the Ever-Cushion™ skin extremely durable to all weather, forces and marine conditions.

D. Various optional fitting designs are available for different requirement. The integral swivel end fittings provide secure point of attachment without obstructing, even when the fender is compressed. The fittings and accessories are constructed of top quality steel (HDG).

Advantages and Features: Applications:

l High Energy Absorption and Low Reaction Force l Ship-to-ship transfers

l Wide Range of Standard and Custom Sizes & Colors l Offshore boat landings

l Tough, nylon filament reinforced polyurethane skin l LNG and oil terminals

l Ultra-tough Unsinkable Design l Shipyards

l Easy Installation and Large standoff distance l Military applications

l Save Port Maintenance Costs, Enhance Port Capacity l Container vessels

l Low Maintenance l Cruise ships

l Burst Resistance, Extremely Safe

l Well Proven Design

Performance List of Standard Capacity:

|

Diameter x Length |

Standard Capacity of Ever-Cushion Marine Fenders | ||||

|

Metric |

English |

Energy Absorption at 60% deflection |

Reaction Force at 60% deflection | ||

|

(mm) |

(ft) |

(ft-kips) |

(ton-m) |

(kip) |

(ton) |

|

1000 x 1500 |

3.3 x 4.9 |

33 |

5 |

47 |

21 |

|

1000 x 2000 |

3.3 x 6.6 |

48 |

7 |

67 |

30 |

|

1200 x 2000 |

3.9 x 6.6 |

64 |

9 |

76 |

34 |

|

1350 x 2500 |

4.4 x 8.2 |

103 |

14 |

109 |

49 |

|

1500 x 3000 |

4.9 x 9.8 |

155 |

21 |

146 |

66 |

|

1700 x 3000 |

5.6 x 9.8 |

196 |

27 |

162 |

73 |

|

2000 x 3500 |

6.6 x 11.5 |

317 |

44 |

222 |

101 |

|

2000 x 4000 |

6.6 x 13.1 |

371 |

51 |

259 |

117 |

|

2200 x 45000 |

7.2 x 14.8 |

500 |

69 |

321 |

146 |

|

2500 x 4000 |

8.2 x 13.1 |

541 |

75 |

305 |

138 |

|

2500 x 5500 |

8.2 x 18.0 |

294 |

110 |

447 |

203 |

|

3000 x 6000 |

9.8 x 19.7 |

1213 |

168 |

571 |

259 |

|

3300 x 4500 |

10.8 x 14.8 |

1007 |

139 |

430 |

195 |

|

3300 x 6500 |

10.8 x 21.3 |

1581 |

219 |

675 |

306 |

Note:

l Actual values may vary ±15% due to variations in materials, temperature, tolerances, and speed of compression.

l Other sizes and capacity models, High Capacity, Extra High Capacity, Super High Capacity, are available up to customers’ requirements.

>> To get more information, please feel free to contact us.